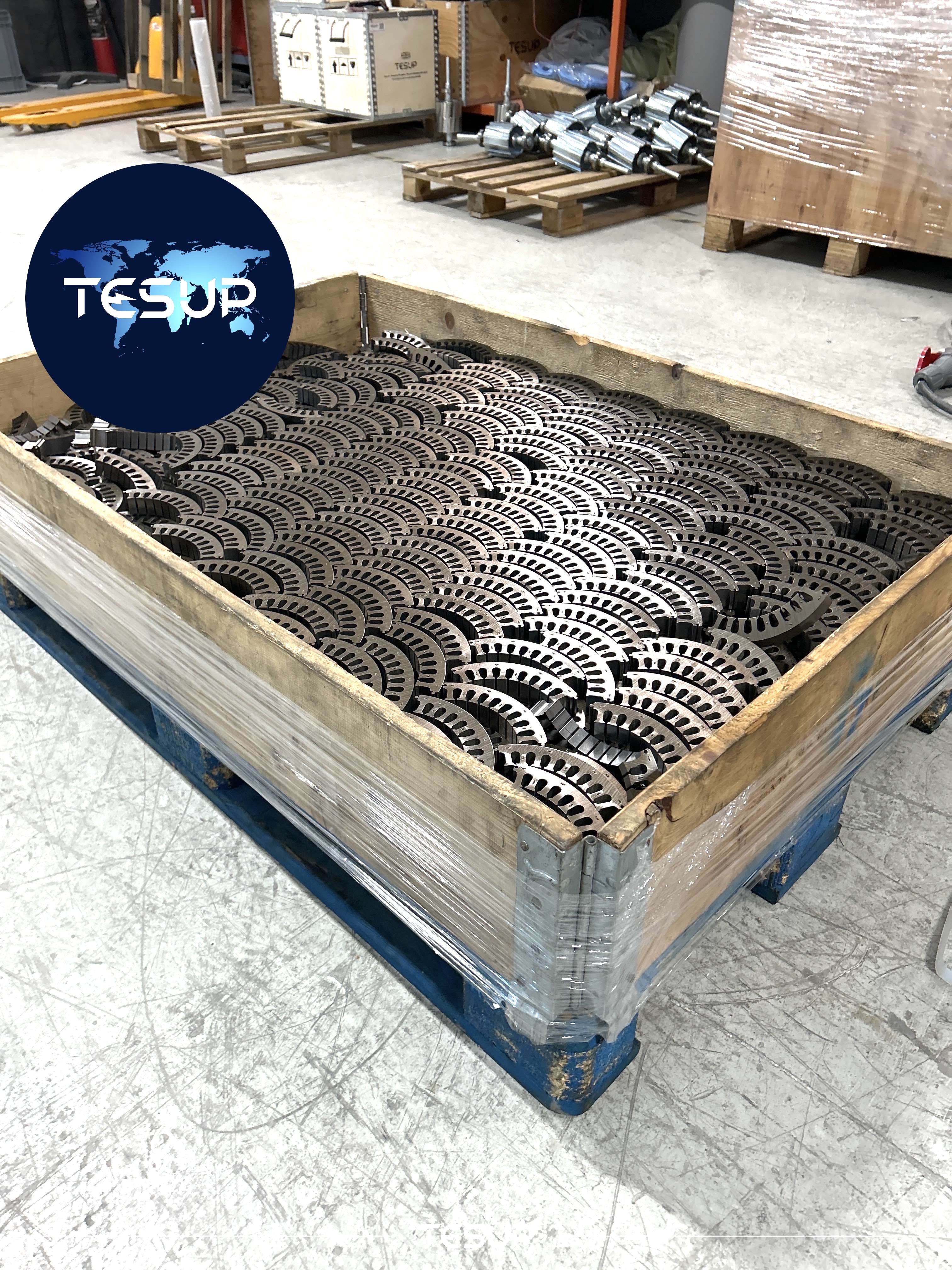

We Cut Thousands of Those Daily

TESUP Global AS takes immense pride in its cutting-edge manufacturing processes, particularly in the field of stator production. Stators are the stationary components of electric motors and generators, playing a crucial role in the conversion of electrical energy into mechanical power or vice versa. The precision, durability, and efficiency of a motor largely depend on the quality of its stator.

Our daily operations involve the cutting and processing of thousands of silicon metal sheets, forming the core structure of stators. Silicon steel is a critical material in motor manufacturing due to its excellent magnetic properties, reduced energy losses, and high efficiency. The careful layering of silicon steel sheets ensures the optimal performance of our stators, contributing to their reliability in demanding applications.

The stator assembly process involves several key stages:

- Core Lamination: Silicon steel sheets are cut into precise shapes and assembled into core laminations. This minimizes eddy current losses, ensuring efficient energy transfer.

- Winding: High-quality copper wires are wound into the stator slots with precision. This step determines the motor's electrical characteristics and performance.

- Insulation: Advanced insulation techniques are employed to enhance the stator's durability and safety, preventing electrical short circuits.

- Testing: Rigorous quality control tests are conducted at every stage to ensure the stator meets TESUP's high-performance standards.

Our innovative approach to stator technology extends beyond traditional manufacturing techniques. TESUP integrates IoT capabilities and custom designs to suit various applications, including renewable energy systems, household appliances, and industrial machinery. By leveraging advanced analytics, we continuously optimize production processes to meet increasing global demand.

In addition to high efficiency, TESUP stators are designed with sustainability in mind. We are committed to reducing waste by recycling silicon steel offcuts and using eco-friendly materials whenever possible. This aligns with our mission to provide renewable energy solutions while minimizing environmental impact.

TESUP stators are incorporated into various products, including our household wind turbines and electric motors. Their reliability and performance have earned the trust of over 100,000 customers worldwide, cementing TESUP's position as a leader in renewable energy technology.

The daily cutting and processing of silicon metals not only showcase TESUP's production capabilities but also underline our commitment to innovation and excellence. As demand for high-quality stators grows, we continue to invest in state-of-the-art machinery and skilled labor, ensuring TESUP remains at the forefront of the renewable energy industry.