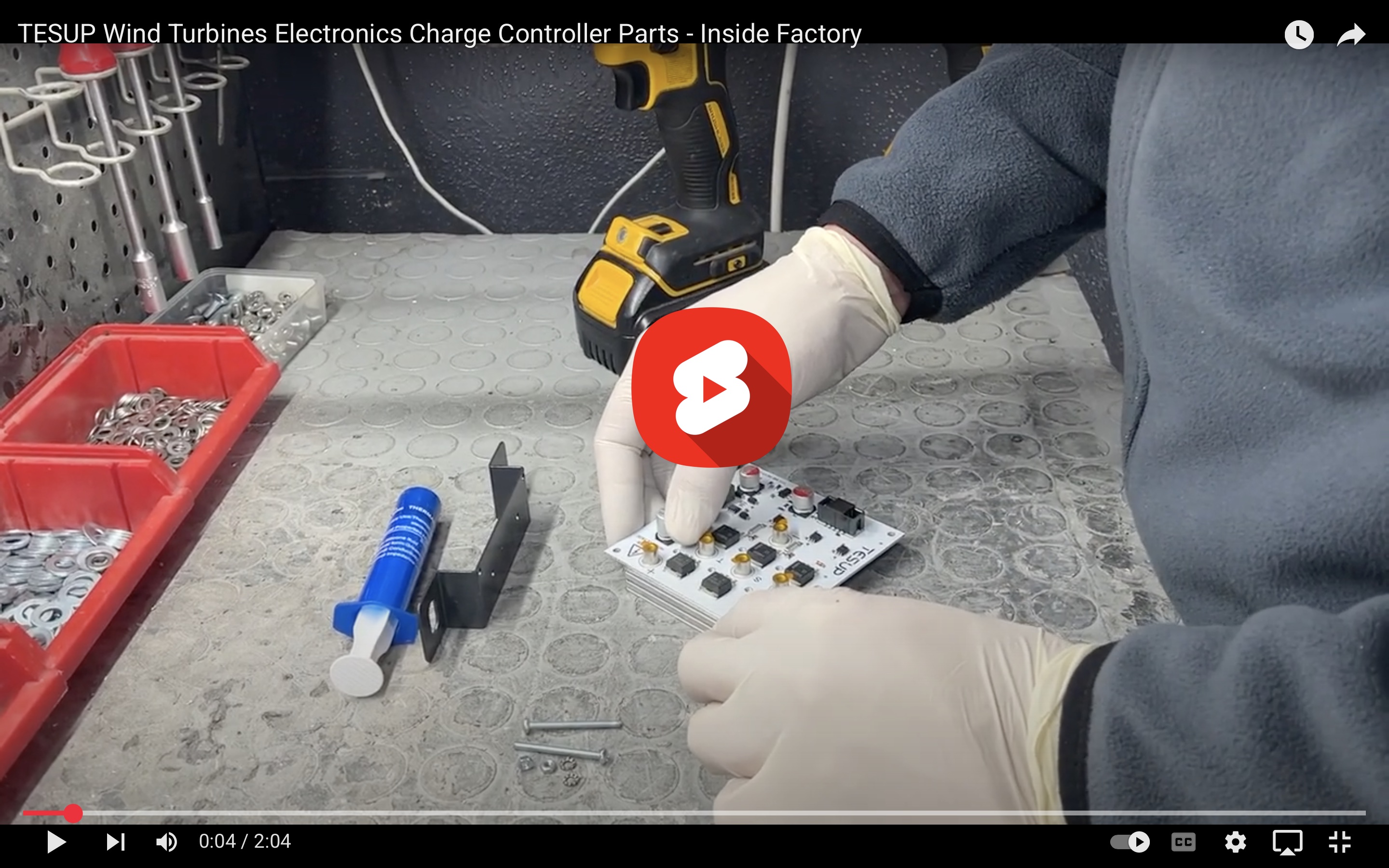

TESUP Charge Controller Step: Cooler Installation Process

At TESUP Factories Europe III Limited, every detail matters when it comes to creating safe, durable, and high-performance renewable energy systems. In this exclusive insight, we take a closer look at a key assembly step within our electronics division: the installation of the cooler component on our wind turbine charge controllers.

This process, while just one part of the overall manufacturing journey, plays a crucial role in ensuring that TESUP charge controllers operate reliably under various weather conditions and wind intensities. Effective cooling directly affects the safety, efficiency, and lifespan of the entire power regulation system.

Why Cooler Installation Matters

Charge controllers regulate and balance the flow of electricity from wind turbines to storage systems, often handling high currents and fluctuating voltages. This generates heat, and without proper dissipation, the electronics could suffer performance loss or permanent damage.

That’s where the cooler comes in — a custom-designed aluminum heat sink fitted precisely onto the controller’s key heat-generating areas. Once installed, it acts as a passive thermal regulator, drawing heat away from sensitive components.

- Helps maintain safe operating temperatures

- Increases durability and performance of the controller

- Designed to integrate seamlessly with TESUP’s circuit board layout

Watch the Cooler Installation Step

Watch the video on YouTube: https://youtu.be/QUVXeu9IexU

This task, although compact in time, reflects our broader manufacturing philosophy — precision, protection, and long-term performance. Our engineers work in a clean, controlled environment with quality checks at every stage to make sure no detail is overlooked.

Designed for TESUP Systems

TESUP charge controllers are custom-developed to integrate seamlessly with our Atlas and Magnum wind turbines. Every cooler is fitted specifically for the layout and thermal characteristics of our printed circuit boards. This compatibility ensures smooth operation across all conditions, from mild breezes to powerful gusts.

And it’s not just about hardware. The intelligent software in TESUP controllers works in sync with the hardware, optimizing energy transfer while keeping safety at the forefront — especially during high-wind events or overload conditions.

Made in Europe. Delivered Worldwide.

This cooler installation step is carried out in our European production line as part of our ongoing commitment to local, high-quality manufacturing. All TESUP electronics, including this charge controller cooler unit, are produced under strict safety and performance protocols, supporting our mission to deliver world-class renewable energy technology from factory to front door.

Our products are shipped to over 32 countries and are supported by responsive local teams to ensure customer satisfaction and long-term reliability.

Learn More

Want to see more of our process or explore our renewable energy products? Visit TESUP.com to discover our wind turbines, flexible solar panels, and advanced energy control electronics.

— By TESUP Factories Europe III Limited