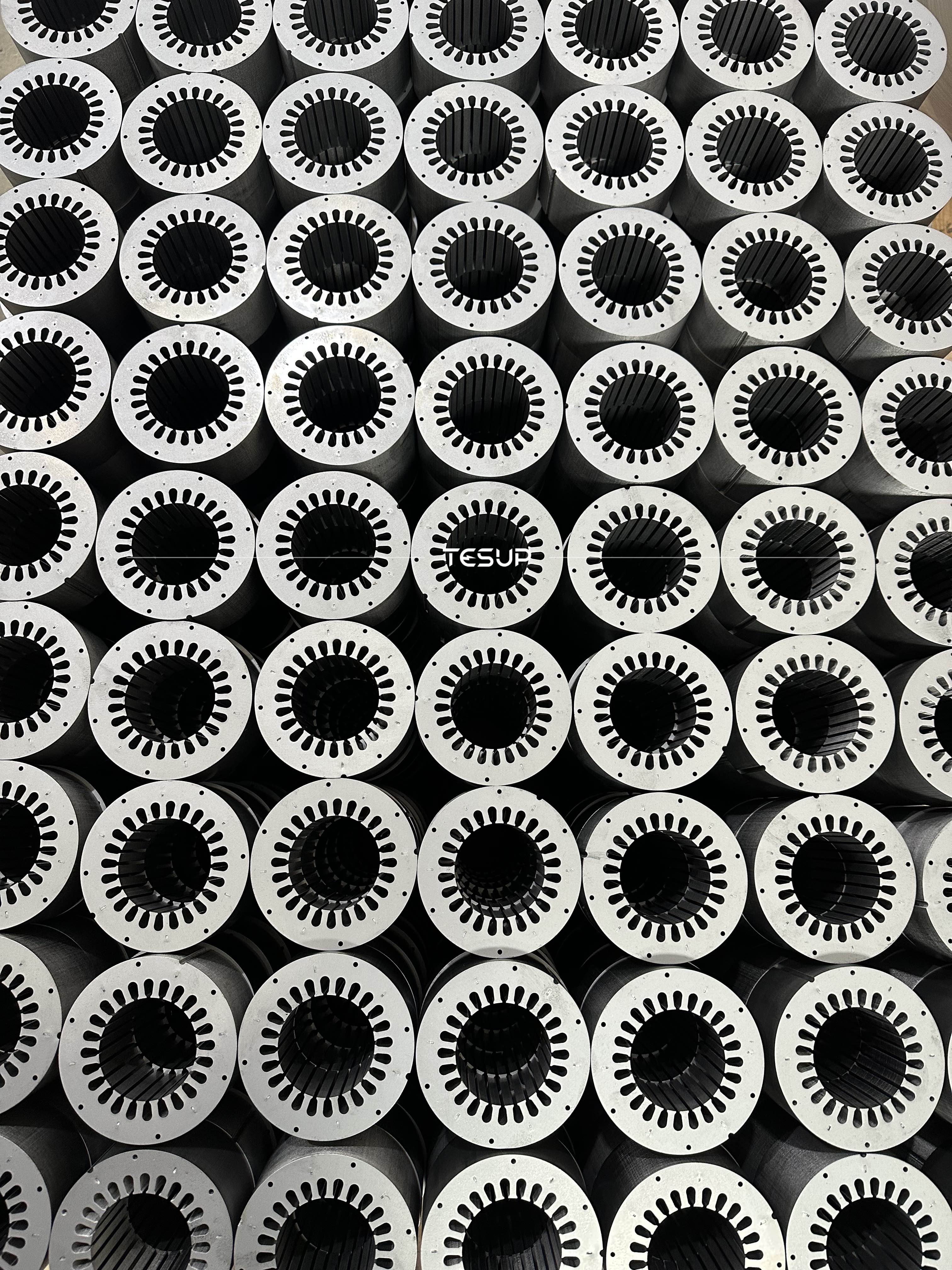

Daily Precision Cutting of Silicon Metals for Motor Manufacturing

Every day at Tesup Motor AS, we begin with a familiar, focused task—cutting high-quality silicon metal sheets that form the foundation of our electric motors. This task, repeated with precision and care, ensures our motors remain consistent, efficient, and powerful no matter where in the world they’re delivered.

Producing motors is more than just manufacturing—it’s a science of repetition, accuracy, and trust in materials. It all starts with a clean, sharp cut of silicon steel.

Silicon Metal: The Heart of Motor Cores

Silicon steel is one of the most important elements in electric motor manufacturing. Its magnetic properties make it ideal for forming laminations—the stacked steel layers inside a motor that direct magnetic flux and reduce electrical losses.

At Tesup, we use only top-grade silicon steel. Our laser-guided cutters ensure perfect symmetry and shape, reducing waste and maximizing energy efficiency. This metal is not only strong but highly responsive to electromagnetic forces—vital for modern energy systems.

Why the Same Job Every Day?

It may sound repetitive, but doing the same task daily is exactly what delivers world-class results. Precision comes from repetition. By focusing on the same production steps every day, we eliminate variability and guarantee top performance across all units.

Every cut we make is part of a standardized process:

- Exact thickness and dimensions of laminations

- Consistent electromagnetic behavior in motors

- High repeatability for bulk manufacturing

- Scalability across continents

Each step is documented and inspected. That’s how we can confidently say our motors are ready for real-world performance—from wind turbines to custom machinery.

TESUP Motor AS: Innovation in Every Rotation

Tesup Motor AS is the specialized branch of TESUP focused solely on motor technology. From our facilities in Europe, we craft every motor component with a blend of industrial power and human precision.

What sets us apart:

- In-house manufacturing and control

- ISO-level quality standards

- IoT integration and performance testing

- Daily assembly of hundreds of motors

Our motors power more than just products—they enable self-sufficiency, renewable integration, and energy security for households and businesses across 32+ countries.

Watch the Process in Motion

See for yourself how we shape and prepare the metals that power tomorrow’s clean energy:

Built to Perform. Built to Last.

Our motors are found in TESUP wind turbines, portable generators, and smart grid systems worldwide. Every single unit is engineered with purpose—lightweight but durable, powerful but efficient.

Thanks to our dedication to using premium silicon metal, we create motors that not only meet expectations but exceed them—especially in demanding off-grid and renewable environments.

Europe-Based. Globally Delivered.

We manufacture in Europe and deliver globally. From our Bratislava plant to distribution centers in the UK and Türkiye, every product is tracked and verified—complete with serial numbers, video documentation, and factory calibration.

By centralizing critical parts like motor core production, we reduce downtime, lower costs, and provide dependable technology for everyone from engineers to everyday families.

Visit TESUP

Want to see more of what we do?

Visit us online: https://tesup.com

Manufactured by: Tesup Motor AS

Conclusion

Silicon metal cutting may seem like a small part of motor production—but in truth, it’s the foundation of everything we build. Our unwavering focus on quality, consistency, and scale allows us to deliver the highest-performing electric motors on the market today.

Thanks to our advanced tools, dedicated team, and daily discipline, we produce hundreds of motors that go on to power clean energy systems worldwide.

From sheet to system—every cut matters.