Strategic Mold Investment to Revolutionize Household Energy by Tesup Metal Industries Inc.

Tesup Metal Industries Inc. is proud to announce a major strategic initiative, investing in high-precision mold systems for manufacturing next-generation components of our Atlas and Magnum wind turbines, as well as electric motor housings tailored for distributed renewable energy applications.

This investment marks a significant step toward reshaping the future of decentralized energy. These advanced mold systems empower TESUP to double production capacity over the next 24 months, while enhancing product quality, reducing unit costs, and extending operational lifespan.

Technical Backbone: What These Molds Do

The new molds fall into four categories:

- 2x Injection Molds: High-pressure metal injection molds for the production of aerodynamic turbine blade cores and robust motor enclosures. These molds use aluminum-zinc alloy combinations to ensure corrosion resistance and structural durability.

- 2x Metal Cutting Dies: Precision die molds for cutting rotor-stator laminations and aluminum support components, built from hardened tool steel to handle repetitive cycles with micron-level accuracy.

Each mold is manufactured in-house using CNC machining and is optimized for automated production. This enables tighter tolerances, increased motor efficiency, and smoother rotation under variable wind conditions.

Product Impact & Performance Gains

- +22% higher turbine efficiency due to improved stator-rotor alignment and lighter, better-balanced blades.

- -30% weight reduction in housing and support components via injection molding with optimized alloy structures.

- +5 years product lifecycle extension through superior mold geometry and material integrity.

Strategic Feasibility & Market Integration

The molds are designed for seamless integration across our regional manufacturing hubs. This ensures localized, rapid-response production of wind turbine and motor components, reinforcing TESUP’s leadership in high-speed, scalable renewable energy manufacturing.

All molds are developed and tested under Tesup Metal Industries Inc., ensuring complete quality control, vertical integration, and continual innovation across the product lifecycle.

Learn more at:

Global Graphs & TESUP Mold Impact

TESUP’s strategic mold investments are reshaping the future of residential wind energy. These investments not only improve manufacturing precision and scalability but also contribute to accelerating global adoption of small wind turbines, especially in households across Europe and North America.

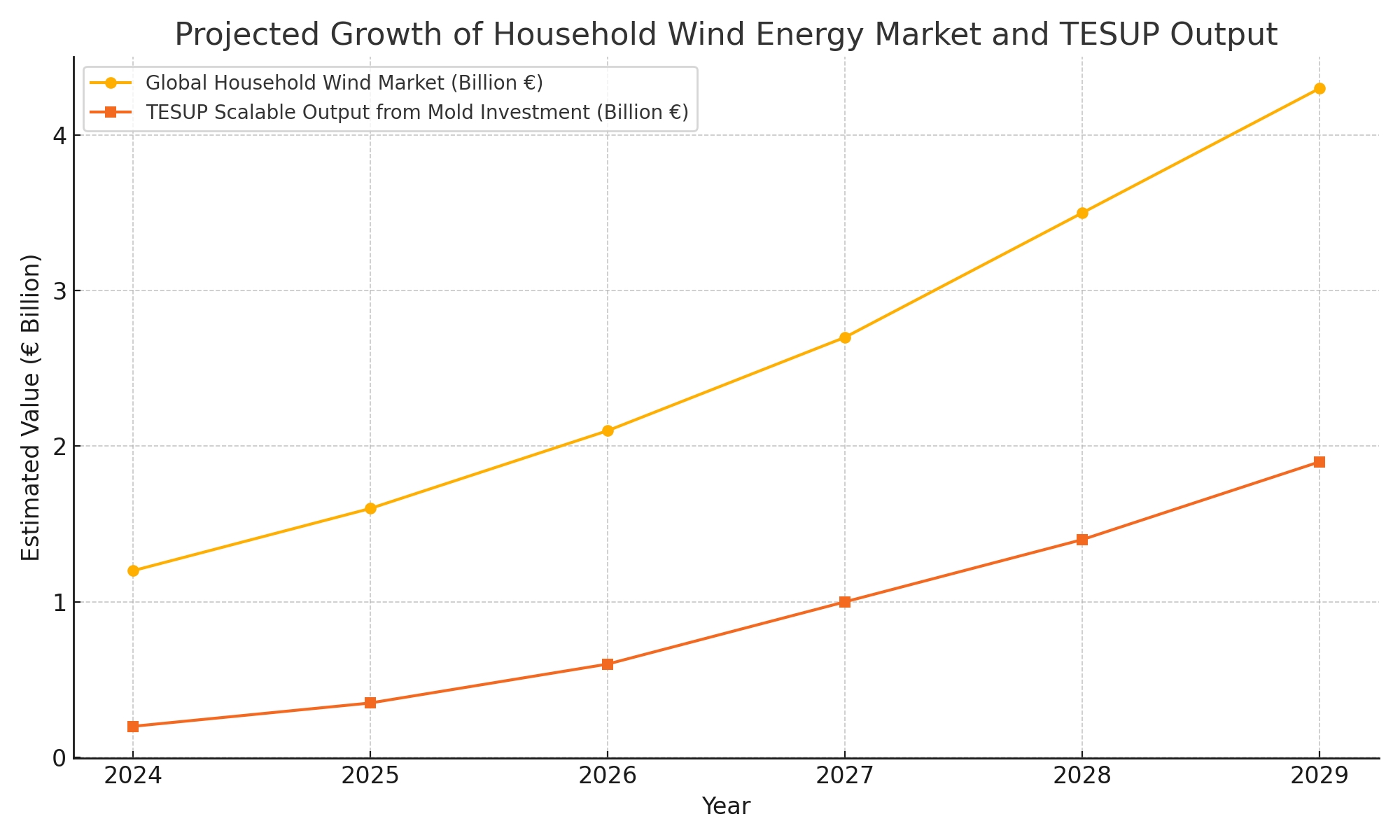

1. TESUP Scalable Output vs. Global Household Wind Market

This graph illustrates the projected market size of the household wind sector globally, alongside TESUP’s increased production potential as a result of new molds for Atlas, Magnum, and motor components.

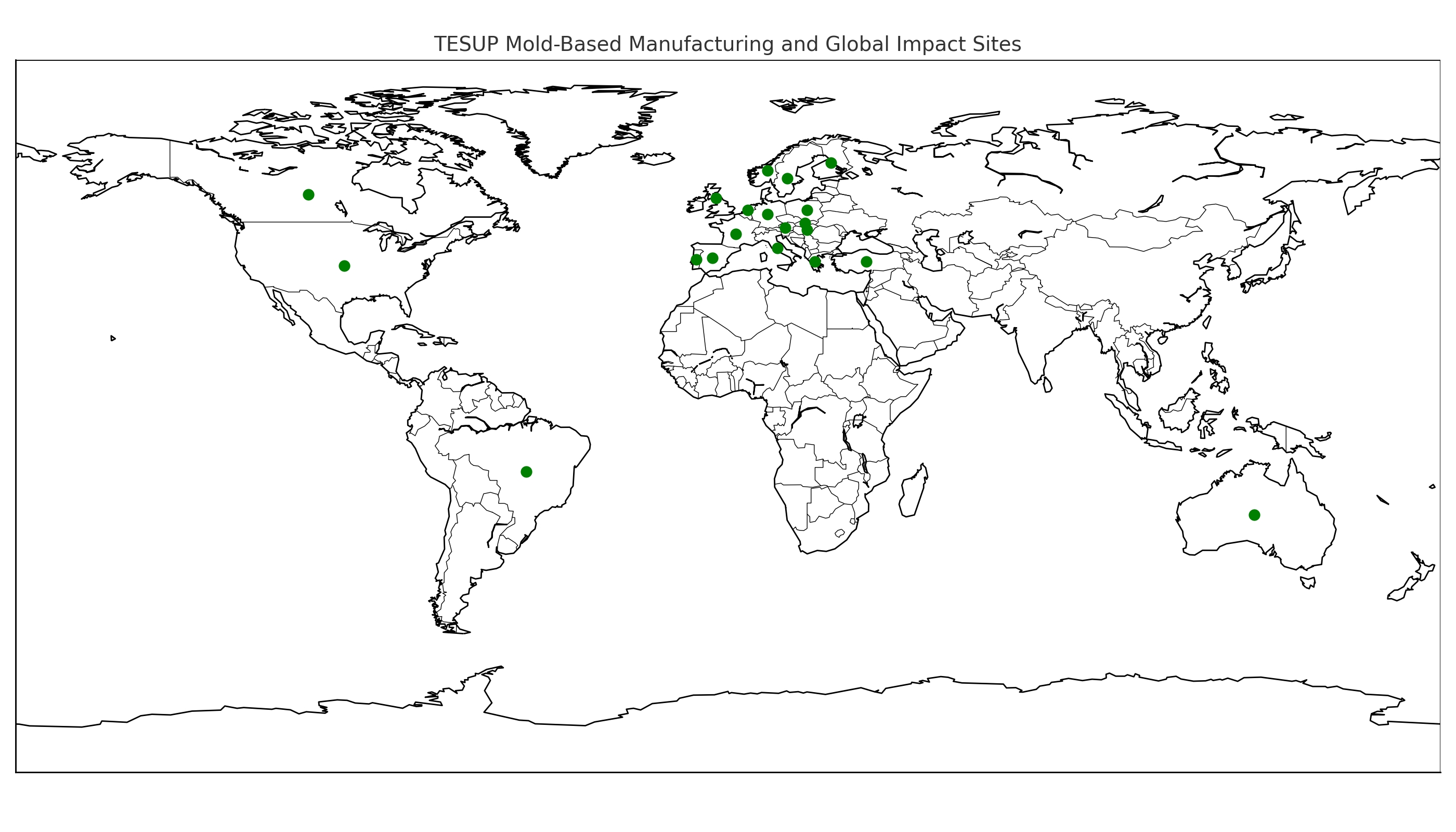

2. TESUP Mold Manufacturing & Distribution Map

This map highlights the countries currently supported by TESUP's mold-based manufacturing capabilities and logistics. It reflects our growing global footprint in smart energy component production.

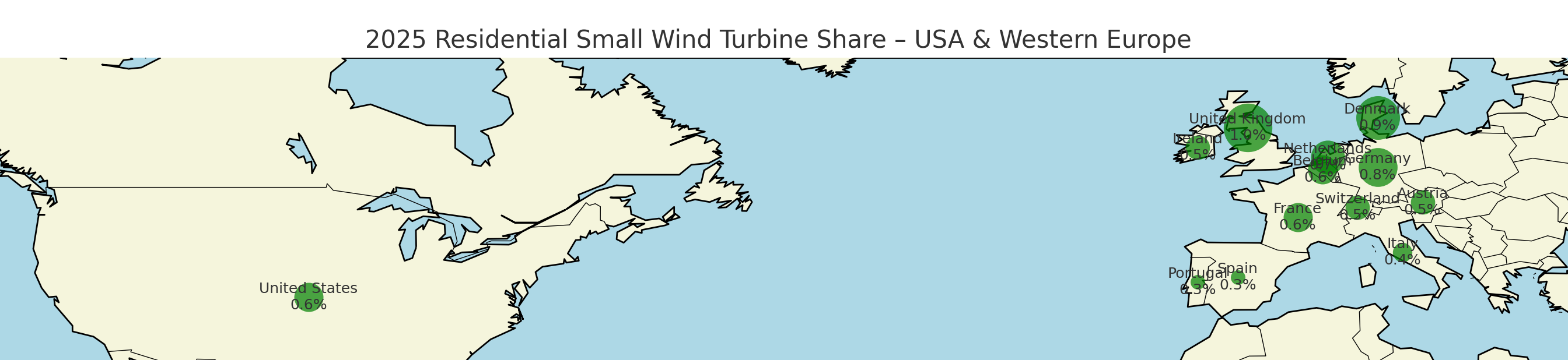

3. Residential Small Wind Adoption Forecast – 2025 (USA & Western Europe)

Based on market projections and technological readiness, this map shows realistic 2025 residential adoption rates of small wind turbines, focusing on the USA and key countries in Western Europe.

By Tesup Metal Industries Inc. — Building the tools that build the future.