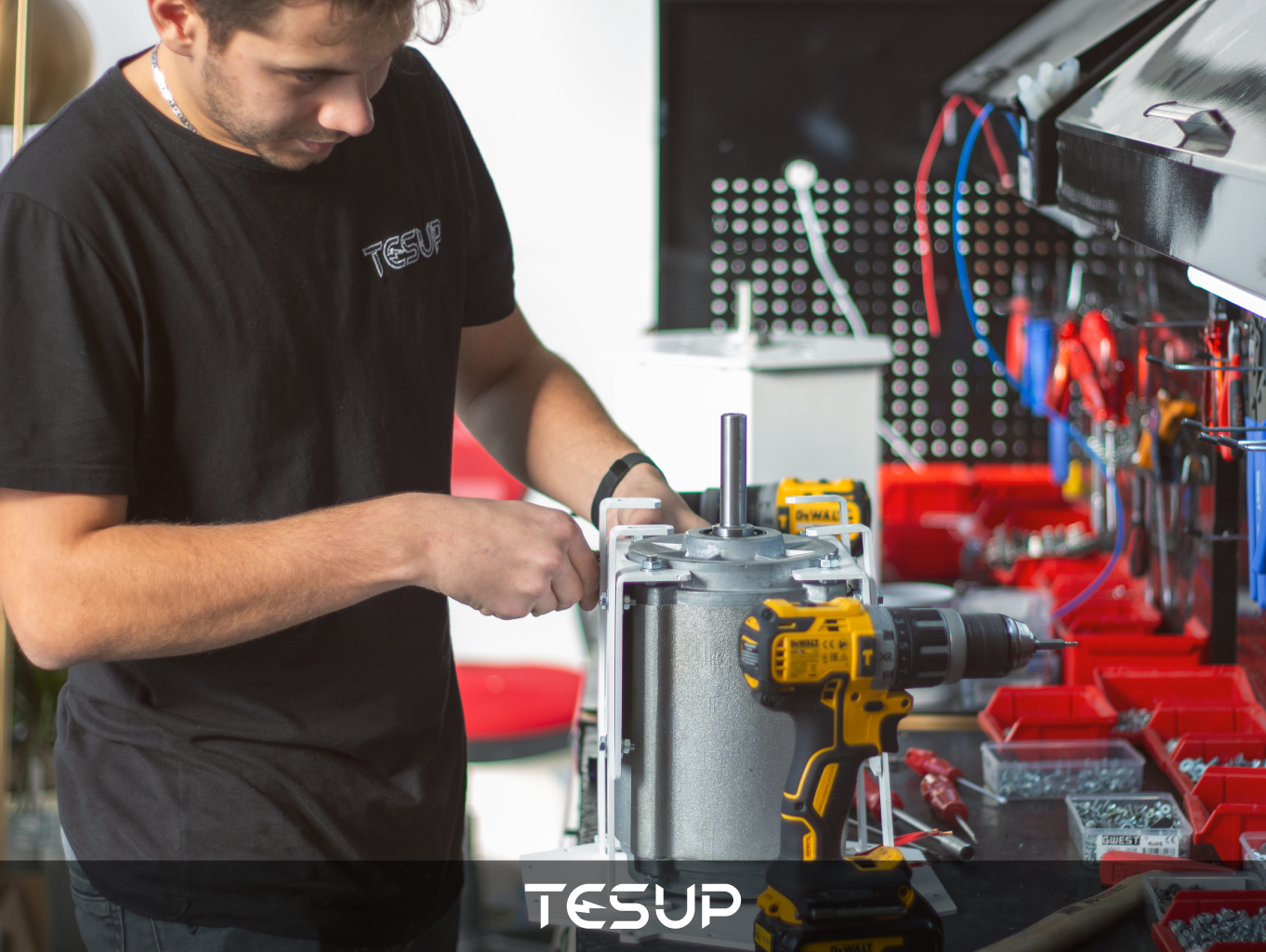

We are proud to announce that despite all the materials shortage Tesup is all set to go for production. Hundreds of Magnum5 and Atlas 4.0 owners will be uniting with their wind turbines very soon.

As the leader of the industry we are determined to provide you with the best product and the service even during these tough times. We believe you can imagine how high Tesup production capacity is regarding the shortage.

The rare element most widely used in every field in electrical companies is N42 strong magnet. A neodymium magnet is the strongest type of permanent magnet available commercially. It is a crucial element in the manufacturing of electric generators for wind turbines, computer hard disks, electrical devices, electric motors. In process industries, powerful neodymium magnets are used to protect products and processes.

It is a fact that there is a shortage of raw materials including N42 strong magnets and electronic chips. The reason for this shortage is due to strong demand and no supply. During the pandemic the demand for work from home technology increased and along with the geopolitical uncertainties these magnets became more essential. These magnets are easy to process into unique shapes and they are only mined in a handful of locations.

But despite the global raw materials shortage in N42 strong magnets and electronic chips, Tesup is planning to manufacture 1000 Atlas and 300 Magnum wind turbine units in 3 weeks.

Also Delta and Growatt Inverters are preparing 1300 low startup voltage grid inverters which are prioritized for TESUP. Low start up voltage is important because the lower the starting voltage, the more efficient the turbine is. At lower wind speed, power is supplied to the grid earlier, thus saving time. In other words, the wind turbine starts working without losing energy.

Tesup is always one step ahead, you will be uniting with your wind turbine very soon!